Optical Coating and Filter

Optical coatings are used to enhance the transmission, reflection, or polarization properties of an optical component. For example, about 4% of incident light will be reflected at each surface of an uncoated glass component. An anti-reflection coating could be applied to reduce the reflection at each surface to less than 0.1% and a highly reflective dielectric coating could also be applied to increase reflectivity to more than 99.99%. An optical coating is composed of a combination of thin layers of materials such as oxides, metals, or rare earth materials. The performance of an optical coating is dependent on the number of layers, their thickness, and the refractive index difference between them. This application note discusses optical coating theory, different types of common coatings, and coating manufacturing methods.

Optical filter and absorbing glasses can be categorized by either the optical behavior of the filter, for example, bandpass, shortpass or longpass, neutral density, or interference filters – or by the method used to filter the light, i.e., glasses which absorb light themselves and those which serve as high quality, transparent substrates for coatings which either absorb or reflect light. The term ‘filter’ usually refers to glasses used in optical systems, to either transmit or prevent transmission of specific wavelengths. The term ‘absorber’ is usually reserved for glasses which are used for controlling light to provide protection from damage to humans, for example, for eye protection, as in sunglasses, or welder and laser goggles, or to materials exposed to light, for example, plastics and other components in the passenger compartment of automobiles.

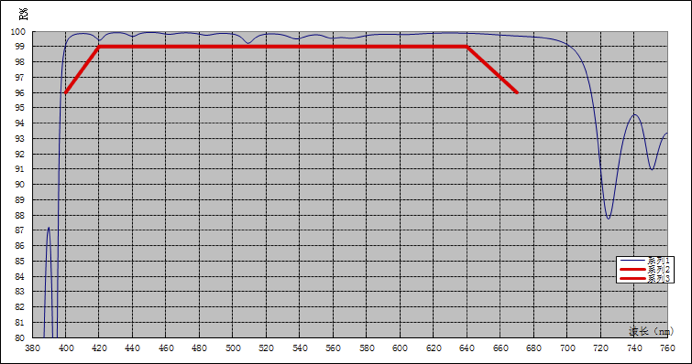

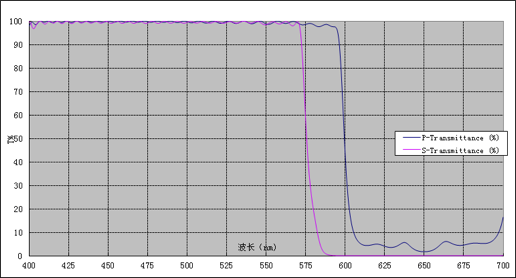

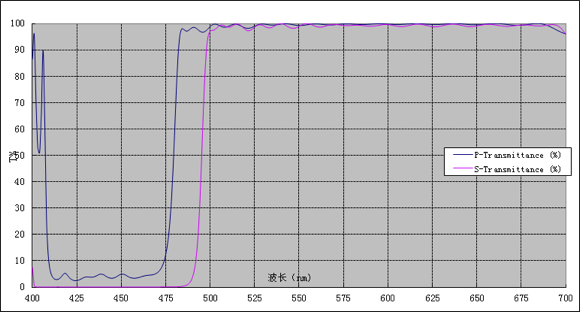

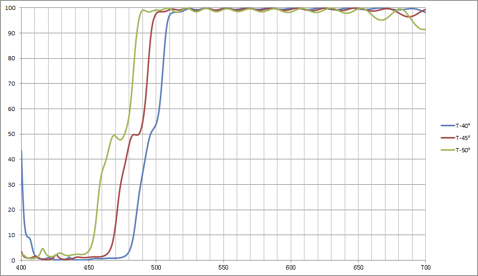

SICUBE has the world's advanced magnetron sputtering optical coating equipment and can design broad-band antireflection, high reflection, dichroism, PBS, narrow-band, semi-transparent, semi-reflective, and other optical coating specifications. To provide customers with filters, reflective plates, dichroic plates, optical low pass filter (OLPF) and other different optical coating products.

Features:

1. kinds of coating specifications

2. covers ultraviolet to infrared band.

3. perfect testing equipment.

4. green production, environmental protection

SICUBE has a 1000-square meters ultra-clean coating workshop, using the world's advanced coating equipment and perfect testing equipment. It can meet the demand of multi specification film from ultraviolet to infrared band

SICUBE can design different types of coating curves according to customer requirements. Its products are suitable for projectors, digital cameras, biological identification, security monitoring, 3D printing, AR display and other fields.